Scaffolding Accessories

Rebar Coupler manufacturer, supplier, and exporter in India

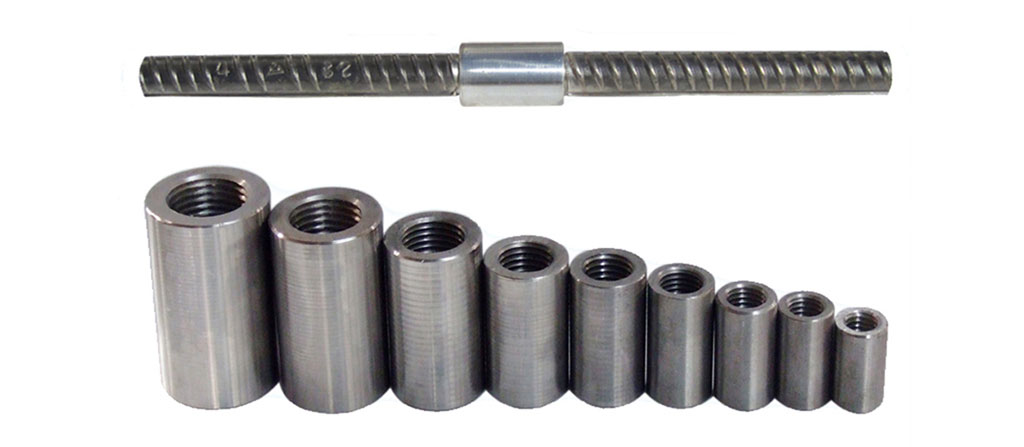

Purchase the cutting-edge Rebar Coupler system from Prime Steeltech, a prominent manufacturer, exporter, and supplier of Scaffolding Accessories based in Mumbai, India. Our Rebar Couplers are engineered to provide seamless and robust connections for reinforcing bars, ensuring optimum load-bearing capacity. With a commitment to excellence, Prime Steeltech delivers a product that meets and exceeds industry standards, guaranteeing a reliable foundation for your projects. Elevate your construction experience with Prime Steeltech's Rebar Coupler, and experience unmatched quality in action.

What is Rebar Coupler?

Features and advantages of Rebar Coupler

- Practical and Economical Alternative: Rebar Coupler serves as a cost-effective and practical substitute for laps in reinforcement bar connections.

- Higher Tensile Strength: It achieves greater tensile strength compared to lap splicing methods, ensuring enhanced structural integrity.

- Simplified Process: Requires only one machine and one operator, streamlining the splicing process.

- Robust and Low Maintenance: Designed for durability, it is sturdy and demands minimal maintenance, contributing to its longevity.

- Efficient Work Time: Takes less than 30 seconds per thread, allowing for swift and efficient splicing operations.

- Corrosion Resistant and Galvanized: Built to withstand corrosion, ensuring longevity and reliability in various environments.

- Easy Installation: No torque wrench is required for installation, simplifying the setup process.

- Proven Design: Tested and proven for reliability and performance, providing confidence in its effectiveness.

- Shortened Construction Cycle Times: Helps accelerate construction projects by reducing the time needed for reinforcement bar splicing.

- Versatile Size Range: Available in sizes ranging from 23.5 mm to 58.6 mm, accommodating a wide range of construction needs.

- Critical in Industries: Indispensable in the construction, oil, and gas industries, ensuring structural stability and safety.

- Enhanced Structural Integrity: Offers higher tensile strength, bolstering the overall strength and stability of reinforced concrete structures.

- Efficiency in Installation: Requires minimal equipment and personnel, making the splicing process straightforward and time-saving.

- Durability and Low Maintenance: Built to last, it is robust and requires minimal upkeep, reducing long-term costs.

- Time-saving: Swift work time per thread ensures quicker project completion, reducing construction timelines.

- Adaptability: Suitable for a wide range of construction projects, contributing to its versatility and usefulness.

- Corrosion Resistance: The galvanized finish ensures resistance to corrosion, making it suitable for diverse environments.

- Proven Performance: Tested design provides confidence in its reliability and effectiveness in reinforcing concrete structures.

Applications of Rebar Coupler

- High-rise Buildings: Rebar Couplers are extensively used in the construction of tall buildings, providing a reliable and efficient method for splicing reinforcement bars.

- Bridges and Viaducts: They play a crucial role in reinforcing concrete structures such as bridges and viaducts, ensuring structural integrity and safety.

- Roads and Highways: Rebar Couplers are employed in the construction of roads and highways to enhance the strength and durability of concrete structures.

- Tunnels: They are used in tunnel construction projects to reinforce the lining and ensure the stability of underground passageways.

- Dams and Reservoirs: Rebar Couplers are essential in the construction of dams and reservoirs, providing the necessary reinforcement for large-scale water infrastructure projects.

- Commercial Complexes: They are utilized in the construction of commercial buildings and complexes, ensuring the structural stability and safety of these structures.

- Railway Infrastructure: They are employed in the construction of railway tracks, bridges, and other infrastructure to ensure the strength and stability of the railway network.

- Airport Facilities: Rebar Couplers play a vital role in the construction of airport terminals, runways, and other facilities, ensuring their structural integrity.

- Residential Complexes: They are used in the construction of residential buildings and housing projects, providing strength and stability to these structures.

- Hospitals and Healthcare Facilities: They play a critical role in the construction of healthcare facilities, providing structural integrity and safety for patients and staff.

- Sports Stadiums and Arenas: Rebar Couplers are used in the construction of sports facilities, ensuring the strength and safety of stadiums and arenas.

- Historical Restoration: They are used in the restoration and preservation of historical buildings, ensuring that these structures maintain their integrity over time.

Prime Steeltech Exports Market Area

At Prime Steeltech, we offer our products across markets to several destinations across globe to several destinations including India and Indian Subcontinent, Asia, Middle East, North America, and South America. Prime Steeltech is committed to customer fulfilment by delivering best quality products at competitive market prices.

| Indian Cities: | ||||||

| Agartala | Bhandara | Dehradun | Imphal | Lakshadweep | Parbhani | Solapur |

| Agra | Bhavnagar | Delhi | Indore | Latur | Patna | Srinagar |

| Ahmedabad | Bhilai | Dhule | Jabalpur | Lucknow | Puducherry | Surat |

| Ahmednagar | Bhiwandi | Dindori | Jaipur | Ludhiana | Pune | Thane |

| Aizawl | Bhopal | Durgapur | Jalandhar | Madurai | Raipur | Thoothukudi |

| Akola | Bhubaneshwar | Erandol | Jalgaon | Malegaon | Rajahmundry | Tirupur |

| Allahabad | Bihar | Faridabad | Jalna | Mangalore | Rajapur | Tripura |

| Amravati | Bikaner | Gadchiroli | Jammu | Meerut | Rajkot | Vadodara |

| Amritsar | Buldhana | Ghaziabad | Jamshedpur | Mumbai | Ramtek | Varanasi |

| Ankleshwar | Chandigarh | Gurgaon | Jhansi | Mysore | Ranchi | Visakhapatnam |

| Asansol | Chandrapur | Guwahati | Kanpur | Nagpur | Ratlam | Warangal |

| Assam | Chennai | Gwalior | Karad | Nanded | Ratnagiri | Wardha |

| Aurangabad | Chimur | Haridwar | Khed | Nandurbar | Raver | Washim |

| Bangalore | Coimbatore | Hatkanangle | Kochi (Cochin) | Nashik | Sangli | Yavatmal |

| Baramati | Dadar and Nagar Haveli | Hingoli | Kolhapur | Nellore | Satara | Pune |

| Beed | Dahanu | Hospet | Kolkata | Noida | Shirdi | Salem |

| Bellary | Daman and Diu | Hyderabad | Kopargaon | Osmanabad | Shirur | Thiruvananthapuram |

| Bhadravati | Darjeeling | Ichalkaranji | Kozhikode | Pandharpur | Siliguri | |

| Indian States: | ||||||

| Andhra Pradesh | Chhattisgarh | Himachal Pradesh | Madhya Pradesh | Mizoram | Rajasthan | Tripura |

| Arunachal Pradesh | Goa | Jharkhand | Maharashtra | Nagaland | Sikkim | Uttar Pradesh |

| Assam | Gujarat | Karnataka | Manipur | Odisha | Tamil Nadu | Uttarakhand |

| Bihar | Haryana | Kerala | Meghalaya | Punjab | Telangana | West Bengal |

| Countries: | ||||||

| Afghanistan | Bulgaria | France | Italy | Namibia | Russia | Trinidad and Tobago |

| Algeria | Canada | Gabon | Japan | Nepal | Saudi Arabia | Turkey |

| Angola | Chile | Gambia | Jordan | Netherlands | Serbia | Ukraine |

| Argentina | China | Germany | Kazakhstan | Nigeria | Singapore | United Arab Emirates |

| Australia | Colombia | Ghana | Kenya | Norway | Slovakia | United Kingdom |

| Austria | Costa Rica | Greece | Kuwait | Oman | South Africa | United States |

| Azerbaijan | Croatia | Hong Kong | Lebanon | Pakistan | South Korea | Venezuela |

| Bahrain | Czech Republic | Hungary | Libya | Peru | Spain | Vietnam |

| Bangladesh | Denmark | India | Lithuania | Philippines | Sri Lanka | Yemen |

| Belarus | Ecuador | Indonesia | Macau | Poland | Sweden | Zimbabwe |

| Belgium | Egypt | Iran | Malaysia | Portugal | Switzerland | New Zealand |

| Bhutan | Estonia | Iraq | Mexico | Puerto Rico | Taiwan | |

| Bolivia | Europe | Ireland | Mongolia | Qatar | Thailand | |

| Brazil | Finland | Israel | Morocco | Romania | Tibet | |

about your requirement to select the right products for your application needs!

Do you have any questions or need help with our services and products?

Submit an Enquiry Form request or Call us at +919393161504

WhatsApp

WhatsApp