Scaffolding Products

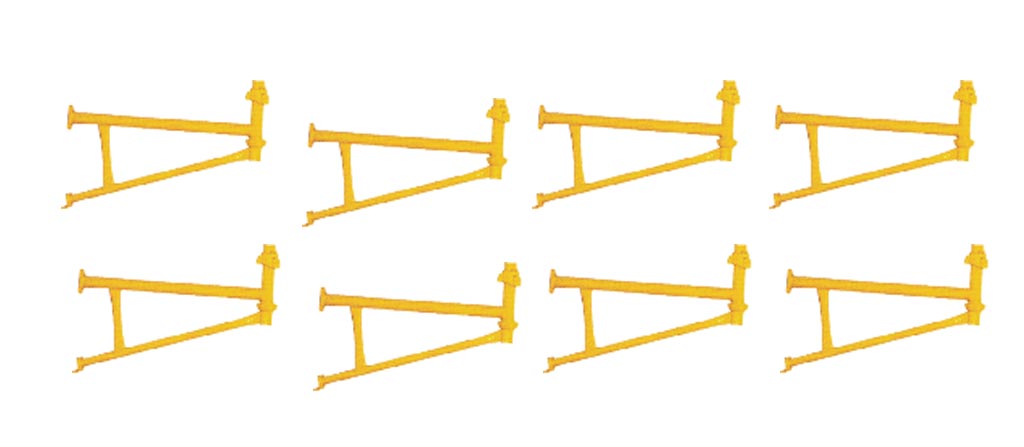

Hop-Up Bracket manufacturer, supplier, and exporter in India

Look no further than Prime Steeltech, a renowned name in the industry. When it comes to premium Hop-Up Brackets, we stand as a beacon of excellence. As one of the largest manufacturers, exporters, and suppliers of Cuplock Scaffolding Systems in Mumbai, India, Prime Steeltech has garnered a reputation for delivering unparalleled quality and reliability. With a commitment to precision engineering and an unwavering dedication to customer satisfaction, we set the gold standard in the field. Elevate your projects with confidence – purchase our Hop-Up Brackets and experience scaffolding excellence like never before.

What is Hop-Up Bracket?

Features and advantages of Hop-Up Brackets

- High Tensile Structural Steel with Hot Dip Galvanized Finish: Crafted from robust structural steel, the Hop-Up Bracket is fortified with a hot dip galvanized finish, ensuring exceptional strength and corrosion resistance.

- Expanding Working Platform Width: This bracket is designed to significantly widen the working platform, allowing for the placement of additional boards and thereby enhancing productivity.

- Handrail Post Location Point: It provides a designated location for securing a handrail post if needed, enhancing safety measures on the scaffold.

- Wedge Lock System, No Loose Fittings: The Hop-Up Bracket utilizes a secure wedge lock system, eliminating the need for screws or nuts. This ensures a stable and reliable platform without any loose components.

- Exceptional Durability: Constructed from tough materials, the Hop-Up Bracket is engineered to withstand the rigors of construction environments, offering long-lasting benefits.

- Low Maintenance Costs: Its robust construction and corrosion-resistant finish mean that the Hop-Up Bracket requires minimal upkeep, resulting in cost savings over its lifespan.

- Customizable Specifications: The bracket's dimensions, surface finish, material, and style can be tailored to specific project requirements, providing versatility and adaptability.

- Labour-Saving Design: A standout feature of this scaffold is its ease of assembly and dismantling. It can be swiftly erected and taken down, saving valuable labour time and effort.

Applications of Hop-Up Bracket

- Extended Working Platforms: Hop-Up Brackets are primarily used to widen the working platform, allowing for the placement of additional boards. This is crucial for tasks that require a larger working area, such as painting, plastering, or bricklaying.

- Support for Additional Boards: They provide essential support for extra boards beyond the inside face of the scaffold, ensuring stability and safety for workers.

- Handrail Post Attachment: These brackets serve as designated points for attaching handrail posts, enhancing safety measures by providing additional support and fall protection.

- Façade Work: Hop-Up Brackets are invaluable for tasks involving the exterior of a building, such as installing windows, cladding, or conducting repairs and maintenance.

- Masonry Work: They are commonly used in masonry projects where a broader working platform is required for tasks like bricklaying or block laying.

- Concrete Work: Hop-Up Brackets play a vital role in concrete construction, providing a stable platform for workers to pour and finish concrete.

- Painting and Finishing Work: These brackets are essential for tasks that involve painting, finishing, or applying coatings to walls or ceilings.

- Roofing Projects: Hop-Up Brackets are employed in roofing tasks, providing a secure platform for workers to access and work on the roof.

- Gutter Installation and Repair: They are used in gutter-related tasks, providing a stable platform for workers to install or repair gutters.

- Light Fixtures and Electrical Work: They can be used to support workers during the installation or maintenance of light fixtures and electrical components.

Prime Steeltech Exports Market Area

At Prime Steeltech, we offer our products across markets to several destinations across globe to several destinations including India and Indian Subcontinent, Asia, Middle East, North America, and South America. Prime Steeltech is committed to customer fulfilment by delivering best quality products at competitive market prices.

| Indian Cities: | ||||||

| Agartala | Bhandara | Dehradun | Imphal | Lakshadweep | Parbhani | Solapur |

| Agra | Bhavnagar | Delhi | Indore | Latur | Patna | Srinagar |

| Ahmedabad | Bhilai | Dhule | Jabalpur | Lucknow | Puducherry | Surat |

| Ahmednagar | Bhiwandi | Dindori | Jaipur | Ludhiana | Pune | Thane |

| Aizawl | Bhopal | Durgapur | Jalandhar | Madurai | Raipur | Thoothukudi |

| Akola | Bhubaneshwar | Erandol | Jalgaon | Malegaon | Rajahmundry | Tirupur |

| Allahabad | Bihar | Faridabad | Jalna | Mangalore | Rajapur | Tripura |

| Amravati | Bikaner | Gadchiroli | Jammu | Meerut | Rajkot | Vadodara |

| Amritsar | Buldhana | Ghaziabad | Jamshedpur | Mumbai | Ramtek | Varanasi |

| Ankleshwar | Chandigarh | Gurgaon | Jhansi | Mysore | Ranchi | Visakhapatnam |

| Asansol | Chandrapur | Guwahati | Kanpur | Nagpur | Ratlam | Warangal |

| Assam | Chennai | Gwalior | Karad | Nanded | Ratnagiri | Wardha |

| Aurangabad | Chimur | Haridwar | Khed | Nandurbar | Raver | Washim |

| Bangalore | Coimbatore | Hatkanangle | Kochi (Cochin) | Nashik | Sangli | Yavatmal |

| Baramati | Dadar and Nagar Haveli | Hingoli | Kolhapur | Nellore | Satara | Pune |

| Beed | Dahanu | Hospet | Kolkata | Noida | Shirdi | Salem |

| Bellary | Daman and Diu | Hyderabad | Kopargaon | Osmanabad | Shirur | Thiruvananthapuram |

| Bhadravati | Darjeeling | Ichalkaranji | Kozhikode | Pandharpur | Siliguri | |

| Indian States: | ||||||

| Andhra Pradesh | Chhattisgarh | Himachal Pradesh | Madhya Pradesh | Mizoram | Rajasthan | Tripura |

| Arunachal Pradesh | Goa | Jharkhand | Maharashtra | Nagaland | Sikkim | Uttar Pradesh |

| Assam | Gujarat | Karnataka | Manipur | Odisha | Tamil Nadu | Uttarakhand |

| Bihar | Haryana | Kerala | Meghalaya | Punjab | Telangana | West Bengal |

| Countries: | ||||||

| Afghanistan | Bulgaria | France | Italy | Namibia | Russia | Trinidad and Tobago |

| Algeria | Canada | Gabon | Japan | Nepal | Saudi Arabia | Turkey |

| Angola | Chile | Gambia | Jordan | Netherlands | Serbia | Ukraine |

| Argentina | China | Germany | Kazakhstan | Nigeria | Singapore | United Arab Emirates |

| Australia | Colombia | Ghana | Kenya | Norway | Slovakia | United Kingdom |

| Austria | Costa Rica | Greece | Kuwait | Oman | South Africa | United States |

| Azerbaijan | Croatia | Hong Kong | Lebanon | Pakistan | South Korea | Venezuela |

| Bahrain | Czech Republic | Hungary | Libya | Peru | Spain | Vietnam |

| Bangladesh | Denmark | India | Lithuania | Philippines | Sri Lanka | Yemen |

| Belarus | Ecuador | Indonesia | Macau | Poland | Sweden | Zimbabwe |

| Belgium | Egypt | Iran | Malaysia | Portugal | Switzerland | New Zealand |

| Bhutan | Estonia | Iraq | Mexico | Puerto Rico | Taiwan | |

| Bolivia | Europe | Ireland | Mongolia | Qatar | Thailand | |

| Brazil | Finland | Israel | Morocco | Romania | Tibet | |

about your requirement to select the right products for your application needs!

Do you have any questions or need help with our services and products?

Submit an Enquiry Form request or Call us at +919393161504

WhatsApp

WhatsApp