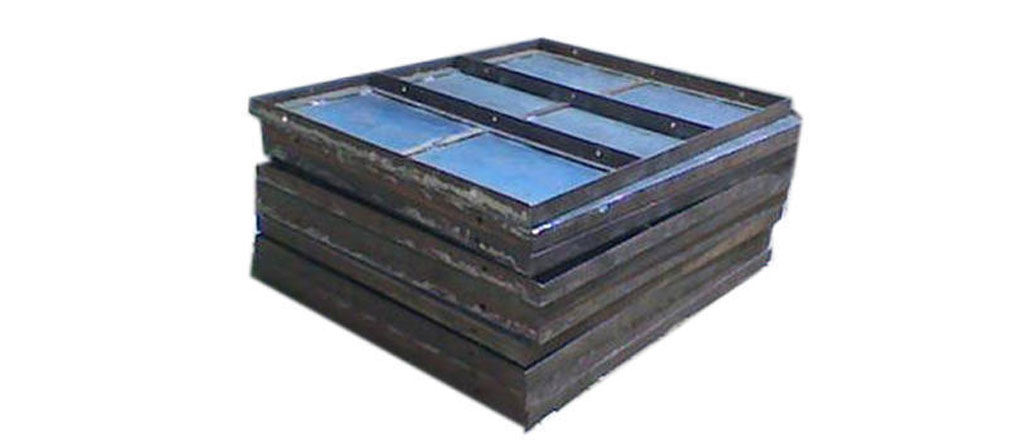

Shuttering Accessories

Centering Sheets manufacturer, supplier, and exporter in India

Your search ends here at Prime Steeltech, a premier manufacturer, exporter, and supplier of Shuttering Products based in Mumbai, India. With a reputation for excellence and a commitment to delivering products of unmatched quality, Prime Steeltech stands as one of the largest providers in the industry. Our Centering Sheets are crafted with precision, ensuring durability and reliability on every construction site. Whether you're involved in a small-scale endeavour or a large-scale industrial project, trust Prime Steeltech to provide the essential components you need. Explore our extensive range of Centering Sheets and experience the pinnacle of craftsmanship and performance.

What is Centering Sheets?

Features and advantages of Centering Sheets

- Highly Dimensionally Accurate and Durable: Centering Sheets are precision-engineered to exact specifications, ensuring a tight fit and long-lasting performance. Their robust construction makes them capable of withstanding the rigors of construction environments.

- Resistant and Corrosion-Resistant Finish: Designed to endure harsh conditions, Centering Sheets come with a corrosion-resistant finish. This protective coating shields them from environmental elements, enhancing their longevity and performance.

- Welded and Riveted Angles: The inclusion of welded and riveted angles further reinforces the structural integrity of Centering Sheets, providing additional stability and support during construction activities.

- Two Types Available: Centering Sheets are available in two types: Sheet metal folding (14 SWG) and Sheet metal with ANG. This variety ensures flexibility in selecting the most suitable option for specific project requirements.

- Enhanced Structural Integrity: The precise engineering and durable materials used in Centering Sheets contribute to the overall stability and structural integrity of the formwork.

- Corrosion Resistance: The corrosion-resistant finish protects the sheets from rust and deterioration, ensuring they remain effective and reliable even in challenging environmental conditions.

- Variety of Sizes and Specifications: With multiple size options and angle provisions, Centering Sheets can be tailored to suit specific project needs, providing a versatile solution for various construction applications.

- Streamlined Construction Process: The use of Centering Sheets facilitates a smoother and more efficient construction process, saving time and labor costs on the construction site.

- Durable and Long-Lasting: Manufactured with high-quality materials, Centering Sheets are built to withstand the demands of construction environments, providing long-lasting performance.

-

Specifications:

- Sizes Available: 600 x 900 and 600 x 1250

- Provision of Angle: 35 x 35 x 5 mm thick, 30 x 30 x 3 mm thick, and 25 x 25 x 5 mm thick

Applications of Centering Sheets

- Slab Construction: Centering Sheets provide essential support for concrete slabs during the casting process, ensuring a smooth and level surface.

- Beam Construction: They are used to create formwork for concrete beams, helping maintain the shape and alignment of the beam.

- Column Construction: Centering Sheets are employed to support and stabilize formwork during the pouring of concrete columns, ensuring they are structurally sound.

- Canopy Construction: They play a crucial role in forming canopies, providing the necessary support for concrete pouring.

- Bridge Construction: In bridge projects, Centering Sheets assist in creating formwork for various structural elements, ensuring they meet design specifications.

- Tunnel Construction: They are used in the construction of tunnel linings, providing support for the concrete.

- High-Rise Buildings: Centering Sheets are crucial for constructing tall buildings, supporting formwork for floors, walls, and columns.

- Residential Buildings: They find extensive use in the construction of houses and apartment buildings, supporting various concrete elements.

- Industrial Facilities: Centering Sheets are employed in the construction of industrial structures like factories, warehouses, and manufacturing plants.

- Infrastructure Projects: They are used in diverse infrastructure projects such as dams, water treatment plants, and retaining walls.

Prime Steeltech Exports Market Area

At Prime Steeltech, we offer our products across markets to several destinations across globe to several destinations including India and Indian Subcontinent, Asia, Middle East, North America, and South America. Prime Steeltech is committed to customer fulfilment by delivering best quality products at competitive market prices.

| Indian Cities: | ||||||

| Agartala | Bhandara | Dehradun | Imphal | Lakshadweep | Parbhani | Solapur |

| Agra | Bhavnagar | Delhi | Indore | Latur | Patna | Srinagar |

| Ahmedabad | Bhilai | Dhule | Jabalpur | Lucknow | Puducherry | Surat |

| Ahmednagar | Bhiwandi | Dindori | Jaipur | Ludhiana | Pune | Thane |

| Aizawl | Bhopal | Durgapur | Jalandhar | Madurai | Raipur | Thoothukudi |

| Akola | Bhubaneshwar | Erandol | Jalgaon | Malegaon | Rajahmundry | Tirupur |

| Allahabad | Bihar | Faridabad | Jalna | Mangalore | Rajapur | Tripura |

| Amravati | Bikaner | Gadchiroli | Jammu | Meerut | Rajkot | Vadodara |

| Amritsar | Buldhana | Ghaziabad | Jamshedpur | Mumbai | Ramtek | Varanasi |

| Ankleshwar | Chandigarh | Gurgaon | Jhansi | Mysore | Ranchi | Visakhapatnam |

| Asansol | Chandrapur | Guwahati | Kanpur | Nagpur | Ratlam | Warangal |

| Assam | Chennai | Gwalior | Karad | Nanded | Ratnagiri | Wardha |

| Aurangabad | Chimur | Haridwar | Khed | Nandurbar | Raver | Washim |

| Bangalore | Coimbatore | Hatkanangle | Kochi (Cochin) | Nashik | Sangli | Yavatmal |

| Baramati | Dadar and Nagar Haveli | Hingoli | Kolhapur | Nellore | Satara | Pune |

| Beed | Dahanu | Hospet | Kolkata | Noida | Shirdi | Salem |

| Bellary | Daman and Diu | Hyderabad | Kopargaon | Osmanabad | Shirur | Thiruvananthapuram |

| Bhadravati | Darjeeling | Ichalkaranji | Kozhikode | Pandharpur | Siliguri | |

| Indian States: | ||||||

| Andhra Pradesh | Chhattisgarh | Himachal Pradesh | Madhya Pradesh | Mizoram | Rajasthan | Tripura |

| Arunachal Pradesh | Goa | Jharkhand | Maharashtra | Nagaland | Sikkim | Uttar Pradesh |

| Assam | Gujarat | Karnataka | Manipur | Odisha | Tamil Nadu | Uttarakhand |

| Bihar | Haryana | Kerala | Meghalaya | Punjab | Telangana | West Bengal |

| Countries: | ||||||

| Afghanistan | Bulgaria | France | Italy | Namibia | Russia | Trinidad and Tobago |

| Algeria | Canada | Gabon | Japan | Nepal | Saudi Arabia | Turkey |

| Angola | Chile | Gambia | Jordan | Netherlands | Serbia | Ukraine |

| Argentina | China | Germany | Kazakhstan | Nigeria | Singapore | United Arab Emirates |

| Australia | Colombia | Ghana | Kenya | Norway | Slovakia | United Kingdom |

| Austria | Costa Rica | Greece | Kuwait | Oman | South Africa | United States |

| Azerbaijan | Croatia | Hong Kong | Lebanon | Pakistan | South Korea | Venezuela |

| Bahrain | Czech Republic | Hungary | Libya | Peru | Spain | Vietnam |

| Bangladesh | Denmark | India | Lithuania | Philippines | Sri Lanka | Yemen |

| Belarus | Ecuador | Indonesia | Macau | Poland | Sweden | Zimbabwe |

| Belgium | Egypt | Iran | Malaysia | Portugal | Switzerland | New Zealand |

| Bhutan | Estonia | Iraq | Mexico | Puerto Rico | Taiwan | |

| Bolivia | Europe | Ireland | Mongolia | Qatar | Thailand | |

| Brazil | Finland | Israel | Morocco | Romania | Tibet | |

about your requirement to select the right products for your application needs!

Do you have any questions or need help with our services and products?

Submit an Enquiry Form request or Call us at +919393161504

WhatsApp

WhatsApp